CANADA

USA

About TPP Boilers PVT. LTD

Tubes, Pipes, Boilers for Thermal Power Plants

TPB is a manufacturer & Erector of High Temperature Steam Boiler Pressure Parts, Boiler Components and Fabricator of Replacement Boiler Tube, Water Wall Tubes and Panels, Superheater, Economiser Tubes & Coils, Assemblies, Wall or Steam Header and other Boiler Pressure Parts and Heavy Structures For Large Steam Generator are Custom Fabricated to Precisely Fit your Boiler.

Our Promoters and Promoter Workers have a very deep knowledge and wide experience of over 500 man-years in Fabrication, Erection, Bending & Welding of all kinds of Plates, Sections, Tubes and Pipes like Seamless, ERW, and Rifle-Bore made of any kinds of Steels like Carbon Steels, Alloy Steels, and Stainless Steels in any Size and Length and to any Specification.

Our Products

Economiser Coils

These are boiler feed-water heaters in which the heat from waste flue gases is recovered to raise the temperature of feed water supplied to the boiler, thereby increasing the Fuel Economy, Steaming Capacity, Life of the Boiler and Reducing Pollution.

Superheaters Coils

Superheaters Coils are the most critical Boiler Component of the modern day Thermal Power Plant and are subject to very high metal temperatures. In fact the capacity of the Superheater to work without failure at higher Temperatures is what determines...

Studded Bed Coils & Tubes

Studded Tubes are used to increase the Surface Areas to achieve higher Heat Transfer Rates. They are used in Fluidized Bed Coils and Fluidized Bed Superheaters. They are also used in Refineries as Reheaters. We use Automatic Stud Welding Machines....

Boiler Bank Tubes

Boiler Bank Tubes are Bent to Shape Tubes or Steam Generating Tubes where Water is converted to Steam. Boiler Bank Tubes carry a mixture of water and steam. Fabricated from Tubes in various sizes and shapes, bending of these tubes is generally...

Water Wall Panels

Water Wall Panels are used in modern day Boilers in place of Steam Generating Tubes to reduce heat loss due to their gas tight nature and reduce insulation costs. We fabricate Water Wall Panels using automatic Fin to tubes welding machines and large Tube Panel...

Pipes & Tube

We supply steel pipes, tubes & fitting to various specification with MTC & IBR Certificate In the size range of 8 mm OD to 1016 mm OD x 1 mm Thk to 76.2mm Thk used for steam / line piping, boilers superheaters, economizers, water wall, headers, air pre heaters etc.

Helically Wound Finned Tubes

(Embedded Fin) The G fin strip is wound into a machined groove and securely locked into place by back filling with base tube material. This ensures that maximum heat transfer is maintained at high tube metal temperatures. Maximum operating...

Finned Tubes

While it is not necessary to tell engineers what finned tubes are, or that their use is mandatory in cases of gas-liquid heat exchange where the film coefficient ratio is above 2, it is essential to tell the engineers that FINNED TUBES are backed by not only engineering excellence of manufacture , but also...

Headers

Headers form an important part of all types of boilers. Steam from the generating tubes is collected in headers which are therefore always under pressure. This pressure may vary from 300 psi to 2000 psi. Since headers are always under pressure, the utmost care is taken by us while fabricating them.

Heat Exchangers

For pressure vessels and reaction vessels in M.S., Al, Monel, Inconel, Cupronickel, etc., TPP BOILERS employs the latest techniques for expanding tube ends into tube sheets. High pressure tests are always carried out on these heat exchangers before they leave...

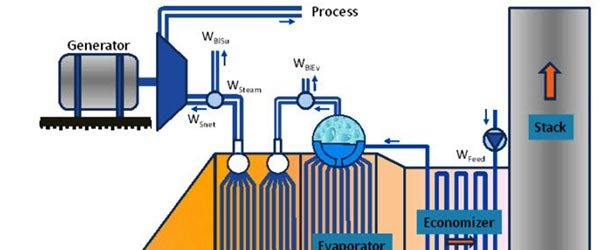

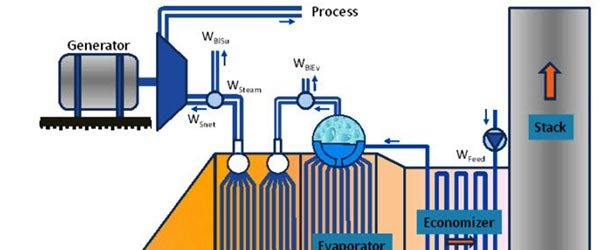

Waste Heat Boilers

These are boiler feed-water heaters in which the heat from waste flue gases is recovered to raise the temperature of feed water supplied to the boiler, thereby increasing the Fuel Economy, Steaming Capacity, Life of the Boiler and Reducing Pollution...

Economiser Coils

These are boiler feed-water heaters in which the heat from waste flue gases is recovered to raise the temperature of feed water supplied to the boiler, thereby increasing the Fuel Economy, Steaming Capacity, Life of the Boiler and Reducing Pollution.

Superheaters Coils

Superheaters Coils are the most critical Boiler Component of the modern day Thermal Power Plant and are subject to very high metal temperatures. In fact the capacity of the Superheater to work without failure at higher Temperatures is what determines...

Studded Bed Coils & Tubes

Studded Tubes are used to increase the Surface Areas to achieve higher Heat Transfer Rates. They are used in Fluidized Bed Coils and Fluidized Bed Superheaters. They are also used in Refineries as Reheaters. We use Automatic Stud Welding Machines using....

Boiler Bank Tubes

Boiler Bank Tubes are Bent to Shape Tubes or Steam Generating Tubes where Water is converted to Steam. Boiler Bank Tubes carry a mixture of water and steam. Fabricated from Tubes in various sizes and shapes, bending of these tubes is generally...

Water Wall Panels

Water Wall Panels are used in modern day Boilers in place of Steam Generating Tubes to reduce heat loss due to their gas tight nature and reduce insulation costs. We fabricate Water Wall Panels using automatic Fin to tubes welding machines and large Tube Panel...

Pipes & Tube

We supply steel pipes, tubes & fitting to various specification with MTC & IBR Certificate In the size range of 8 mm OD to 1016 mm OD x 1 mm Thk to 76.2mm Thk used for steam / line piping, boilers superheaters, economizers, water wall, headers, air pre heaters etc.

Helically Wound Finned Tubes

(Embedded Fin) The G fin strip is wound into a machined groove and securely locked into place by back filling with base tube material. This ensures that maximum heat transfer is maintained at high tube metal temperatures. Maximum operating...

Finned Tubes

While it is not necessary to tell engineers what finned tubes are, or that their use is mandatory in cases of gas-liquid heat exchange where the film coefficient ratio is above 2, it is essential to tell the engineers that...

Headers

Headers form an important part of all types of boilers. Steam from the generating tubes is collected in headers which are therefore always under pressure. This pressure may vary from 300 psi to 2000 psi. Since headers are always under pressure, the utmost care is taken by us while fabricating them.

Heat Exchangers

For pressure vessels and reaction vessels in M.S., Al, Monel, Inconel, Cupronickel, etc., TPP BOILERS employs the latest techniques for expanding tube ends into tube sheets. High pressure tests are always carried out on these heat exchangers before they leave...

Waste Heat Boilers

These are boiler feed-water heaters in which the heat from waste flue gases is recovered to raise the temperature of feed water supplied to the boiler, thereby increasing the Fuel Economy, Steaming Capacity, Life of the Boiler and Reducing Pollution...

Enquire Now

Tubes, Pipes, Boilers for Thermal Power Plants

Address : 69‐70, 4Th Floor, Ashok Chembers, Devaji Ratanji Marg (Bharuch Street), Masjid Bunder (E), Mumbai ‐ 400 009.

Phone : +912223484046 / 1800-22-8772

Email : [email protected]